I constructed this bridge out of balsa wood for a high school physics class. The mass of the finished bridge was 44.85g (1.58 oz. on earth). The bridge was tested by loading to failure at 291 lbf. As can be seen by the asymmetrically crushed wood on the deck, the load application was not perfectly centered and a higher ultimate loading was probably possible. This is a good example of how unforeseen factors can cause design loads to vary from those actually experienced, and is one reason why factors of safety are so important. The adhesive used was general purpose epoxy.

Saturday, September 12, 2009

Turbo

A turbo impeller I made just for fun out of an old obsolete fixture. Yes, I know the housing is a mirror image of what it should be. I guess I wasn't thinking about function the afternoon I made it back in high school, but it's just for looks anyway. The bearing came out of an old hard drive or some other household appliance. Software used was Mastercam. The mill was a Fryer 3-Axis toolroom CNC.

Brass Gavel

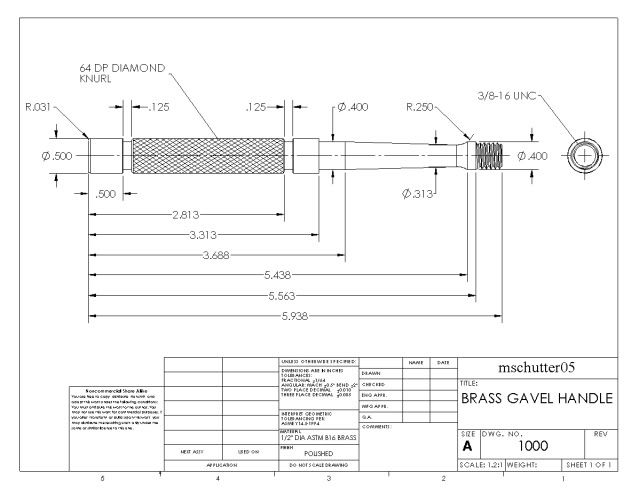

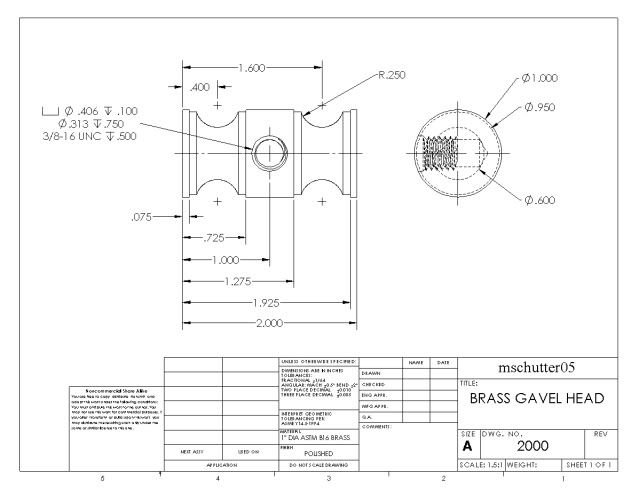

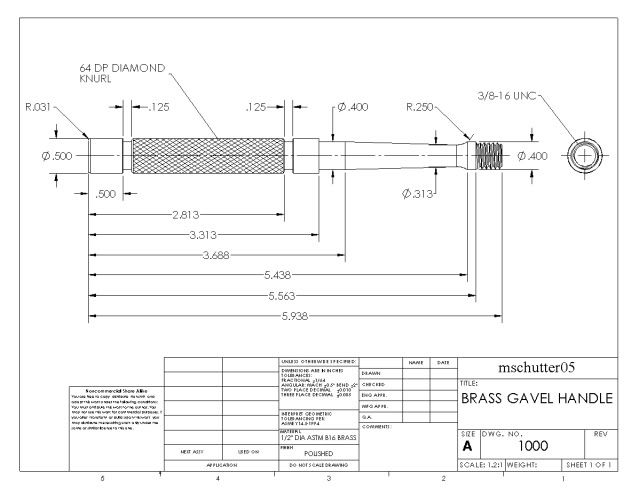

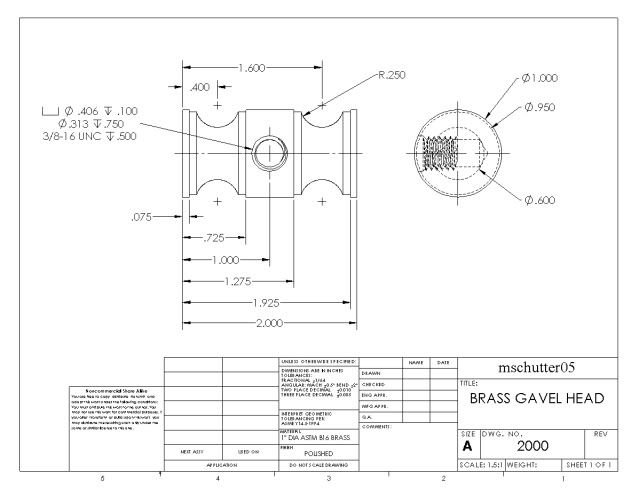

This is a brass gavel I machined in high school on a manual lathe and mill. It features a knurled handle that screws into the counterbored head for a clean connection. Design credit goes to Terry Coss of Newberg High School.

To view and download .pdf files, click the corresponding images below. Part files can be downloaded here.

I made the following video just for fun. In this video I measure and sketch the brass gavel and then model and assemble it in SolidWorks. I do not recommend actually modeling the knurled surface in SolidWorks as this eats up computational resources and wastes time. Just applying a knurled texture to the face would be faster and easier. Although, there is no default knurled brass texture (only steel).

To view and download .pdf files, click the corresponding images below. Part files can be downloaded here.

I made the following video just for fun. In this video I measure and sketch the brass gavel and then model and assemble it in SolidWorks. I do not recommend actually modeling the knurled surface in SolidWorks as this eats up computational resources and wastes time. Just applying a knurled texture to the face would be faster and easier. Although, there is no default knurled brass texture (only steel).

Piston

I have always had dreams of building a miniature V8 engine like Jim Moyer's 1/6th scale Chevrolet 327 cu in V8. One day in shop class during a period in which I must not have had anything better to do I made this piston just for fun. It's really just for looks as there was never any design or drawings to back it up. In fact, if I remember correctly I used a 60° threading tool to cut the piston ring grooves.

Crank Offset

This is a crank offset I made in high school for a low temperature sterling engine similar to American Sterling Company's MM-7 sterling engine. The project was abandoned after a couple days due to other interests and difficulty finding a supplier for the large diameter PMMA tubing (a supplier willing to sell me less than 6' of the stuff that is).

Baseball Bat

A miniature aluminum baseball bat I made in high school. The purpose of this project was to introduce students to the use of live centers as well as turning tapers on manual lathes.

Small Match Holder

This is the smaller one of two capped hollow cylinders (match holders?) I made in high school on a manual lathe. The purpose of this project was to introduce students to basic facing, turning, drilling, and threading operations as they pertain to smaller parts.

Subscribe to:

Comments (Atom)